Injin Soyayyen Dankali na Fozen, Injin Soyayyen Dankali, Injin Yanka Dankali

1. Sauƙin aiki, sauƙin amfani da shi da ƙarancin gazawar aiki.

2. Kula da zafin kwamfuta, dumama iri ɗaya, ƙaramin karkacewar zafin jiki.

3. Ana iya amfani da man na dogon lokaci, kuma yana kiyaye sabo, babu ragowar, babu buƙatar tacewa, ƙarancin yawan carbonization.

4. Cire ragowar da ke cikinsa yayin soya don tabbatar da ɗanɗanon mai.

5. Inji ɗaya yana da amfani da yawa, kuma yana iya soya abinci iri-iri. Ƙarancin hayaƙi, babu ƙamshi, mai dacewa, yana adana lokaci, kuma yana da kyau ga muhalli.

6. Matsayin ƙara yawan sinadarin acid a soya ba shi da kyau, kuma ƙarancin man da aka zubar yana samarwa, don haka launin, ƙamshi da ɗanɗanon soya suna da daɗi, kuma ana kiyaye dandanon asali bayan sanyaya.

7. Tanadin mai ya fi rabin na injinan soya na gargajiya.

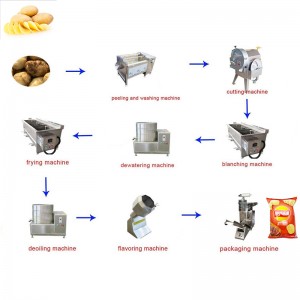

Tsarin sarrafa na'urar sarrafa dankalin turawa ta masana'antu ya ƙunshi tsaftacewa da barewa, yankewa, wankewa, blanching, bushewar ruwa, soya, rage mai, kayan ƙanshi, marufi, kayan aiki na taimako da sauransu. Tsarin musamman na layin samar da dankalin turawa soyayye: ɗagawa da lodawa → tsaftacewa da barewa → rarrabawa → yankewa → wankewa → kurkura → sanyaya iska → soya → deoiling → sanyaya iska → kayan ƙanshi → isar da → marufi.

1. Lif - ɗagawa da lodawa ta atomatik, mai sauƙi da sauri, kuma mai ceton ma'aikata.

2. Injin tsaftacewa da barewa - tsaftace dankali da barewa ta atomatik, adana kuzari.

3. Layin zaɓe - cire sassan dankalin da suka ruɓe kuma suka lalace don inganta inganci.

4. Yankan yanka, wanda za'a iya daidaita shi a girmansa.

5. Mai ɗaukar kaya - ɗagawa da jigilar dankalin turawa zuwa injin wanki.

6. Wankewa-Tsabtace sitaci a saman dankalin turawa.

7. Injin gogewa - hana ayyukan enzymes masu aiki, da kuma kare launi.

8. Na'urar cire girgiza - cire sharar da ta yi ƙanƙanta, sannan a girgiza don cire ruwan da ya wuce kima.

9. Layin sanyaya iska - tasirin sanyaya iska yana cire danshi a saman kwakwalwan dankalin turawa, sannan ya kai su injin soya.

10. Injin soya - soya don canza launi, da kuma inganta yanayin da dandano.

11. Na'urar cire mai daga jiki - Na'urar cire mai daga jiki.

12. Layin sanyaya iska - don cire mai da kuma sanyaya - a hura mai da ya wuce kima a saman, sannan a kwantar da dankalin turawa gaba daya domin su shiga injin dandano.

13. Injin ɗanɗano - yana aiki akai-akai, yana iya ciyarwa da kuma fitar da shi a wani lokaci da aka ƙayyade.

14. Injin shiryawa - gwargwadon nauyin marufin abokin ciniki, marufin dankalin turawa ta atomatik.